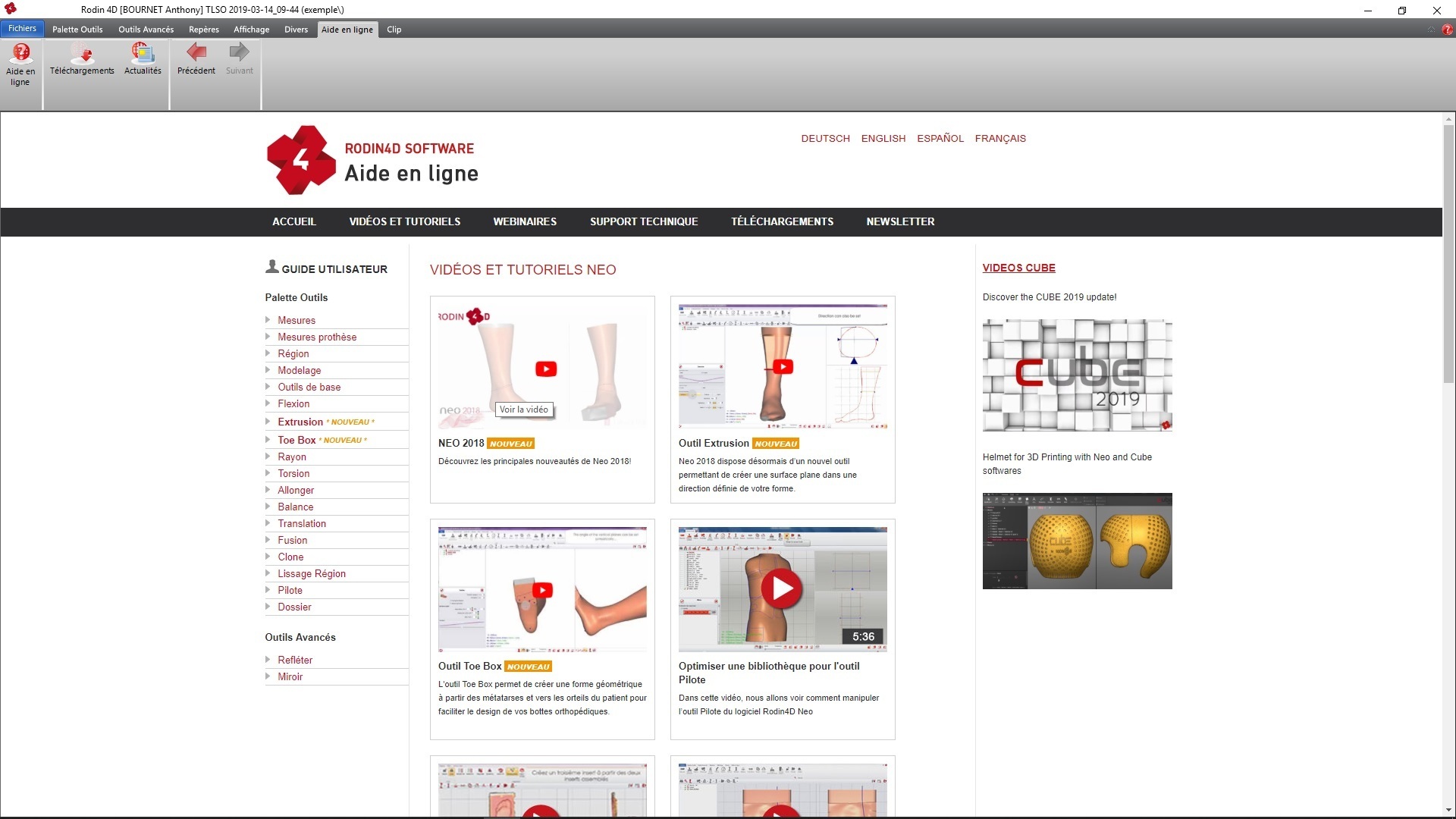

Neo addresses the specific problems of the profession. The value-added essence of CAD/CAM solutions. Neo software has consistently evolved since its creation by orthopaedic technicians 16 years ago. New releases are issued periodically, based on the input received from over 500 professional users.

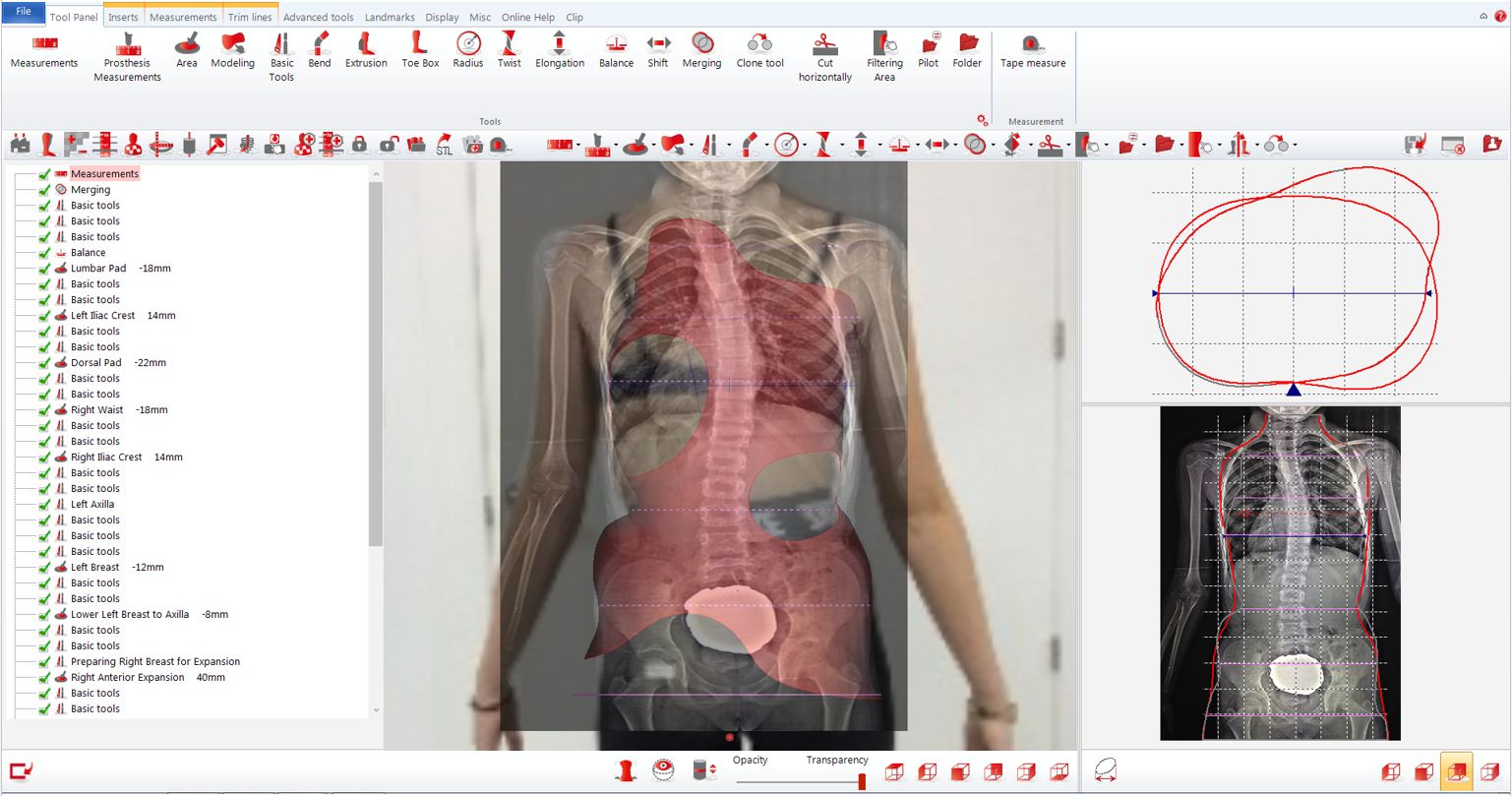

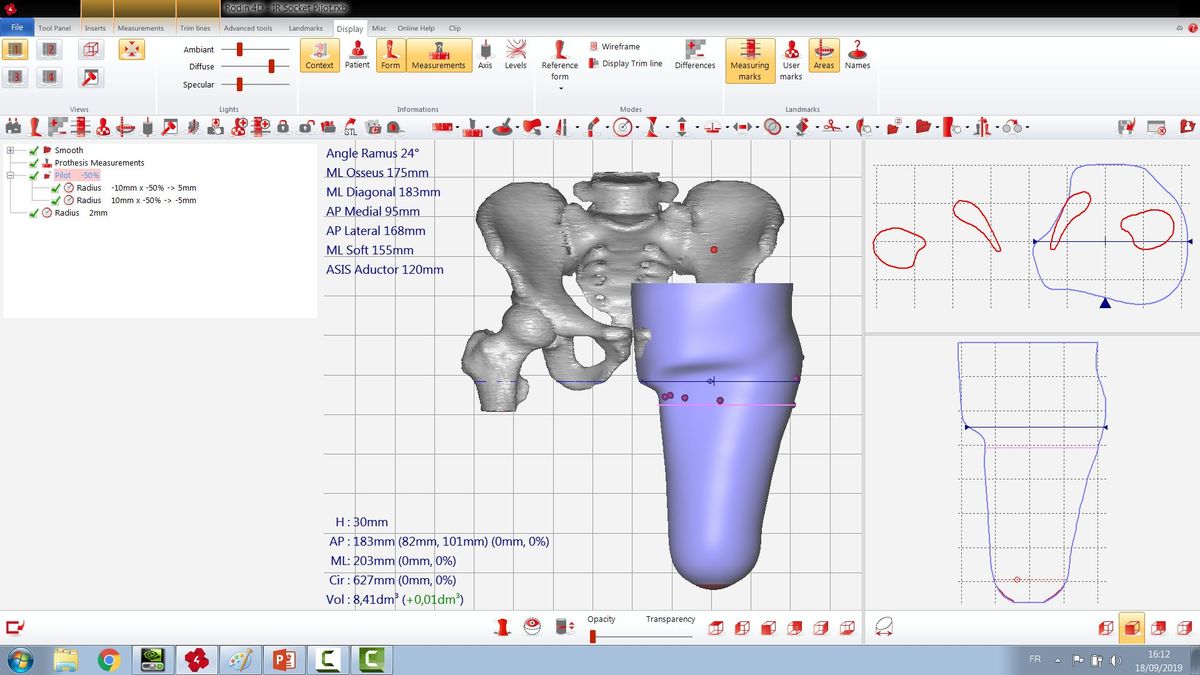

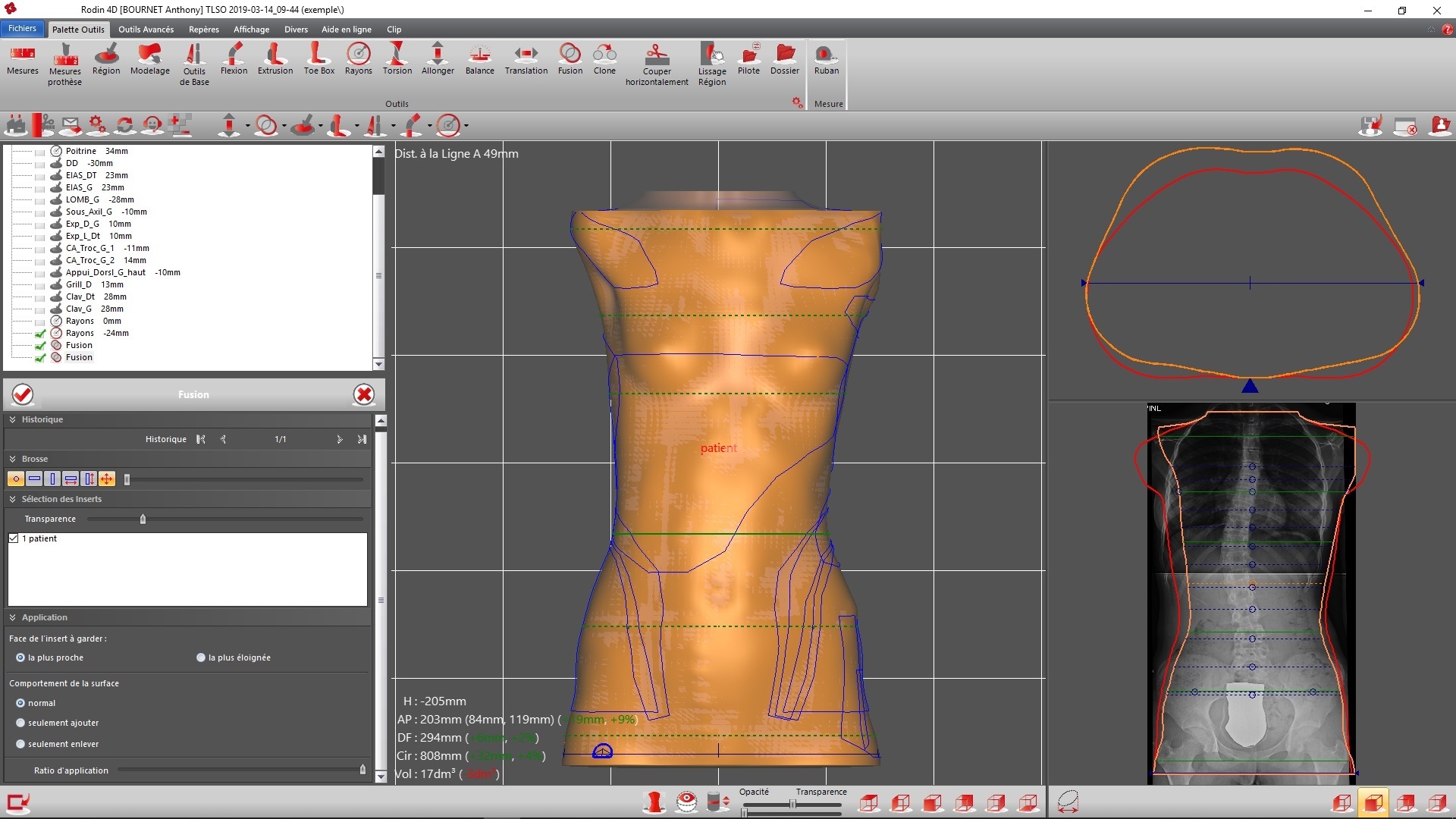

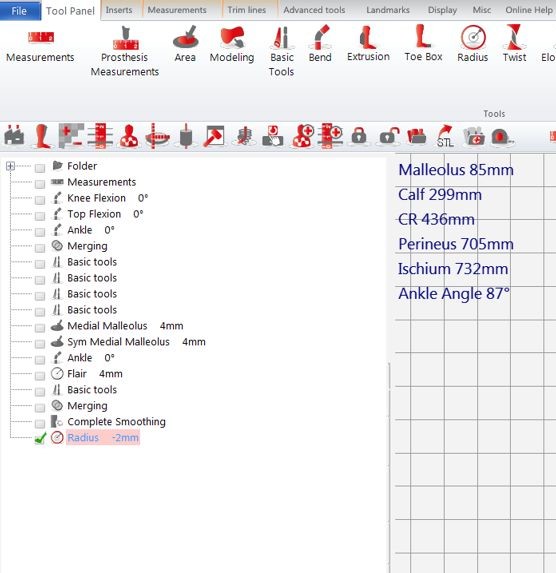

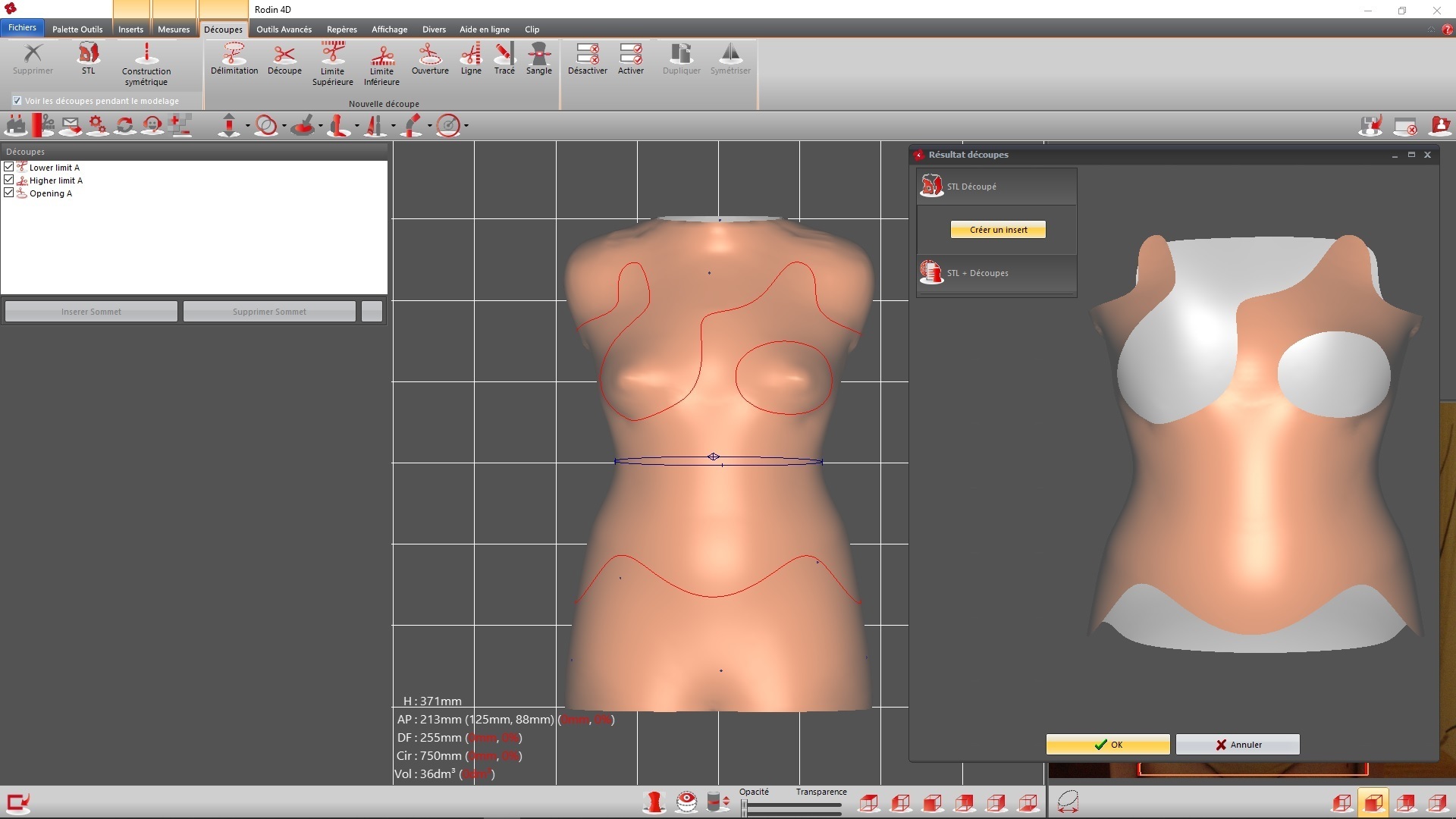

With the simulation tool, you can make form rectifications virtually before sending them to production. You can completely control rectification in the software thanks to a tool library created especially for your work. You can also eliminate a modification stage at any time during rectification.

Neo is compatible with all CAD/CAM solutions on the market and adapts to all equipment thanks to STL file export.