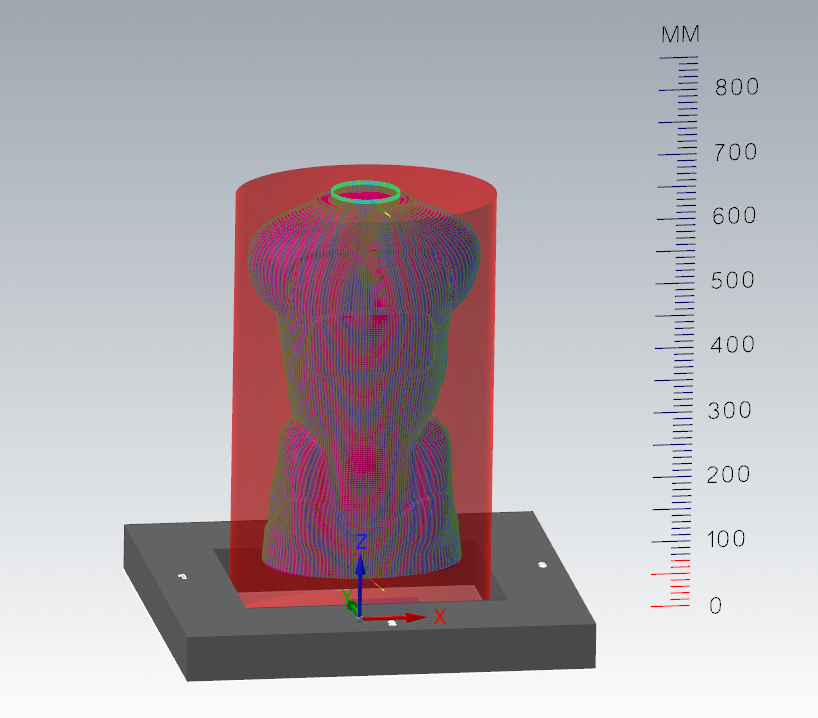

More flexible, the Axelle robot offers you the possibility of optimal management of external axes and extremely fast machining cycles:

- less than 2 minutes for milling a helmet

- less than 5 minutes for a prosthesis

- between 5 and 10 minutes for a corset

The short machining times, the perfect control of the accelerations reducing vibrations and the perfect synchronization of the 7th axis offer an irreproachable finished quality. The speed achieved by the Axelle robot makes it possible to reduce increments and keep cycle times below all current solutions.